Powder Lab

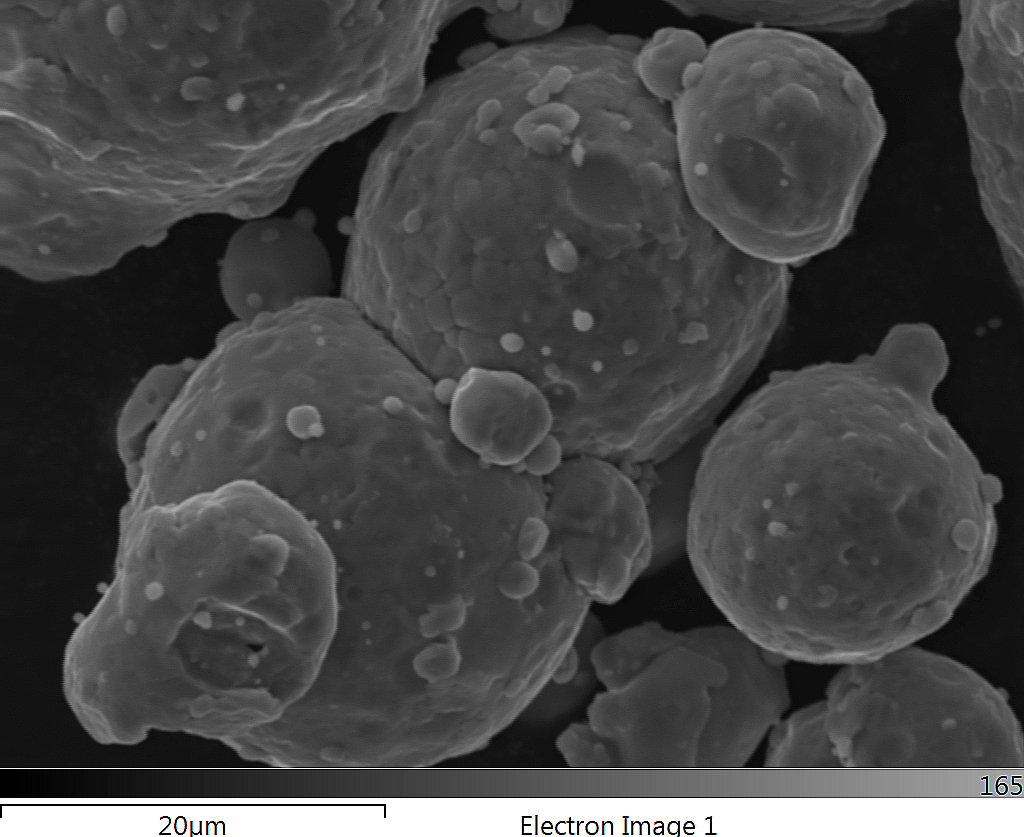

What is the best way to handle 3D printing powder and how does powder quality affect the properties of a printed component?

To answer these questions, powder manufacturers and additive manufacturing service providers will want to know about Laborelec’s brand-new powder lab.

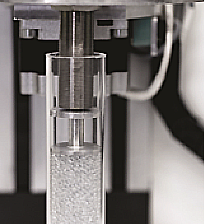

The lab offers a complete set of characterization techniques, as well as deposition and production testing using a flexible selective laser melting machine to provide data on the condition of a powder batch and its behaviour in the additive manufacturing (AM) process.

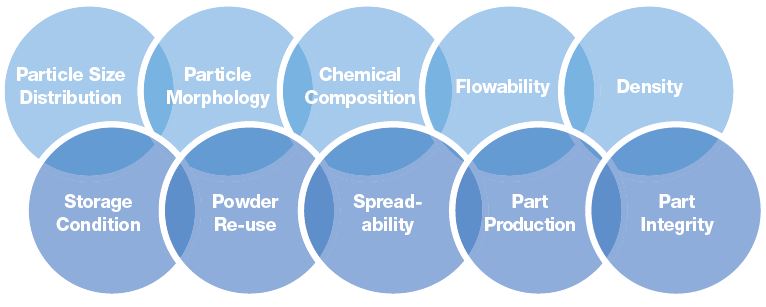

Powder characterisation testing,

conducted according to ASTM norms, results in a product factsheet with full information on:

- Overall powder quality

- Predicted final component quality

- Extended characterisation, including:

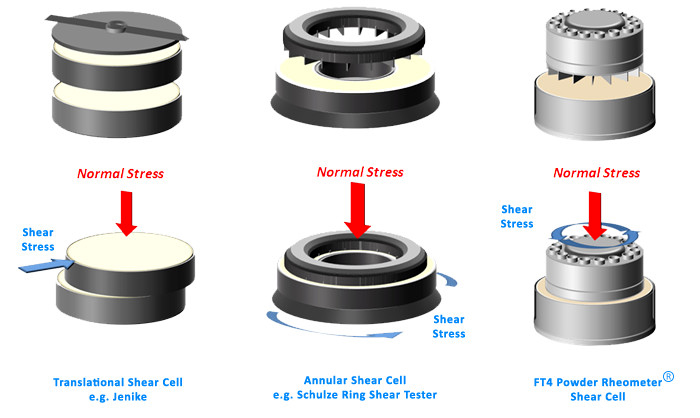

- dynamic powder behaviour

- powder storage

- moisture

- shape factor

Powder is tested new, used or after poor storage conditions. Analysis results in Guidelines on the use of certain powder batches, covering factors such as:

- Shelf-life

- Storage conditions

- Re-use

- Health and safety