Local defects arising in a solar farm can significantly impede its performance, silently impacting the asset’s business case. ENGIE Laborelec offers a unique high quality, cost-effective drone inspection service to precisely identify, locate and qualify any defects. Expert advice helps prioritize corrective measures to maximize return on investment.

WHY

PERFORMANCE AND PROFITABILITY UNDER PRESSURE

Various defects can develop in solar farms during their lifetime. Examples include hotspots, disconnected strings, potential induced degradation (PID), micro-cracks and internal corrosion, and delamination. While each individual defect might have limited impact, defects in combination could significantly impact asset performance and long-term profitability. The problem is that traditional detection methods are laborious and expensive. As a result, solar farm owners and operators forgo the potential performance capability of their installations. ENGIE Laborelec’s cost-effective drone-assisted inspection service and follow-up is here to help.

WHAT

DRONE-ASSISTED DEFECT IDENTIFICATION AND REMEDIATION

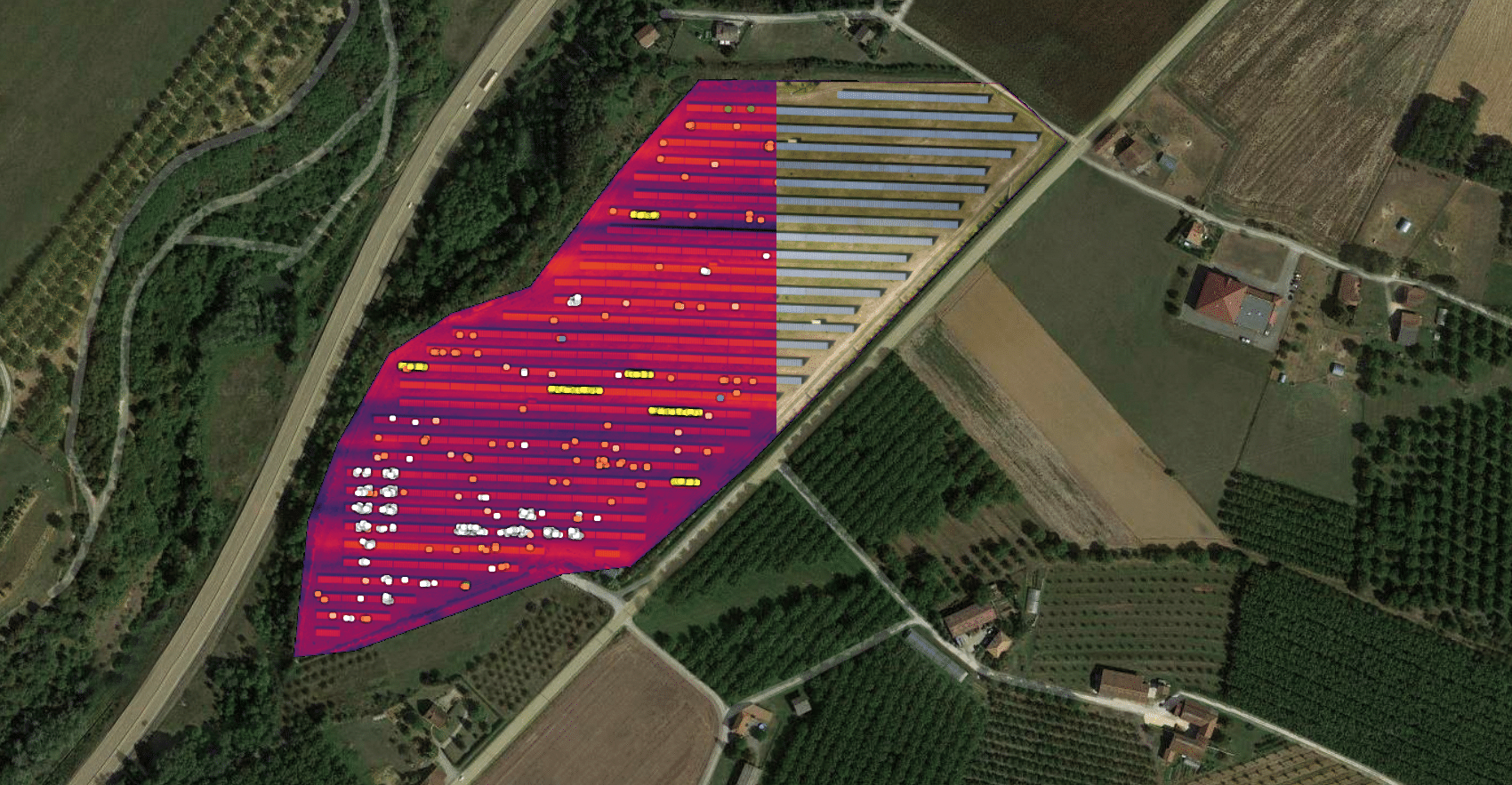

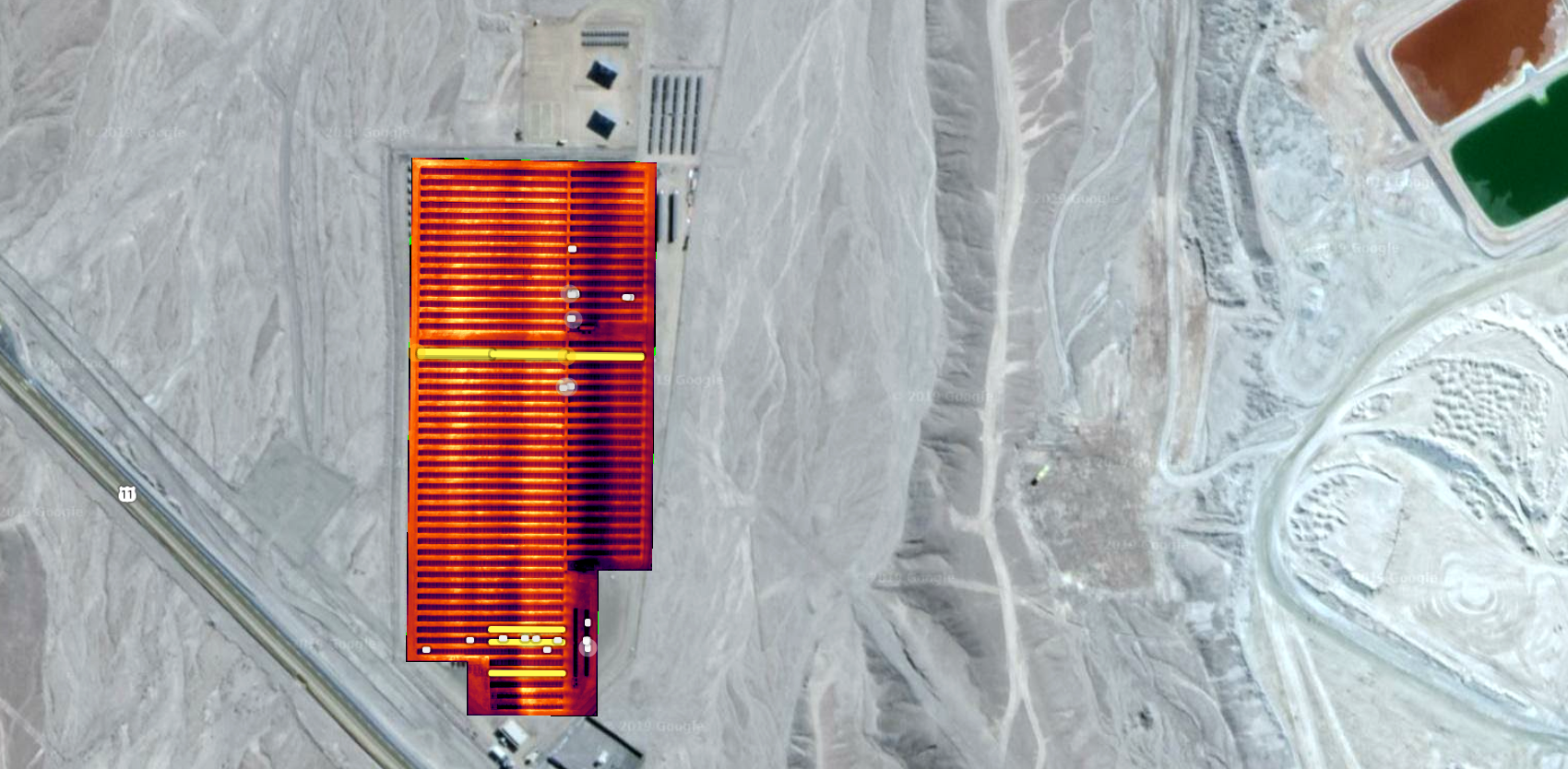

Following an AI-optimized flight plan, one or more drones fly over the solar farm capturing a comprehensive set of high-quality photographic images of various types, including in the infrared spectrum. The images undergo processing to create a 3D model, which is then analyzed using field-validated machine-learning algorithms, producing a map laying out all the identified defects and their location. Targeted maintenance can then be planned. ENGIE Laborelec experts provide hands-on advice on how to prioritize maintenance actions and whether to launch insurance claims.

BENEFITS AND ADDED VALUE

Boosting performance levels

By identifying, analyzing and remediating defects, solar farm owners and operators can maintain high-performance levels and even exceed guaranteed energy production levels.

Maximizing asset profitability

Qualitative and quantitative inspection and analysis allows operators to target and prioritize corrective maintenance actions for maximum asset profitability.

Fast, reliable and invaluable

Drone overflights are planned and carried out by experts with extensive knowledge of solar power technology and its operational realities. This means that data can be collected speedily and reliably. The assessment can be repeated periodically to track trends and benchmark results against other installations.

Experience with complex issues

ENGIE Laborelec experts have many years of experience addressing solar power issues of all kinds, including issues occurring in very complex situations and configurations.

HOW IT WORKS

CONTROLLED IMAGE ACQUISITION

AUTOMATED ANALYSIS AND REPORTING

ADVICE WITH A LONG-TERM VIEW

ENGIE Laborelec experts give hands-on advice to owners and operators, recommending appropriate action predominantly designed to maximize asset lifetime and long-term performance. If needed, additional on-site measurements can be carried out to help owners and operators make the most appropriate decisions. Clients are also advised on possible insurance claims where relevant.