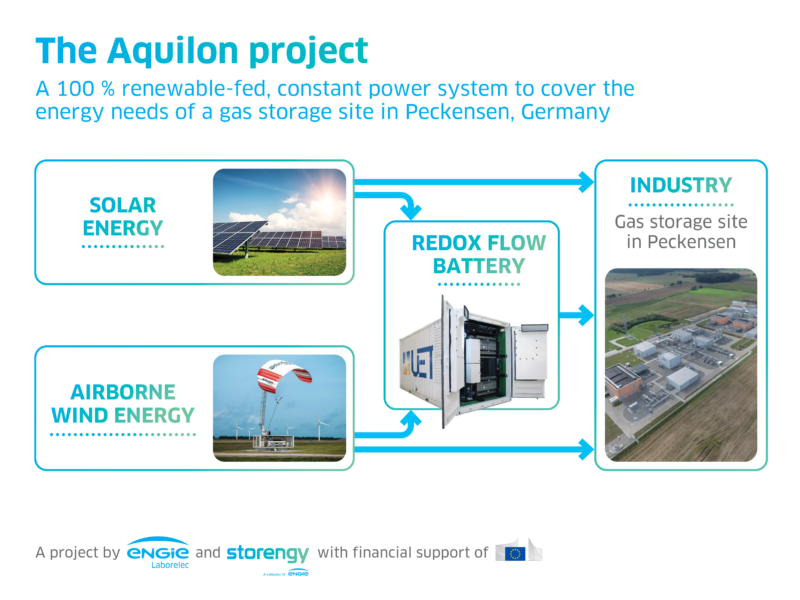

A 100% renewable-fed, constant power system is being developed by Storengy Deutschland GmbH, in collaboration with ENGIE Laborelec, to cover the energy needs of Peckensen gas storage site (Germany)… and more!

An inspired, integrated solution, the “Aquilon” project will demonstrate making best use of clean energy technologies to avoid 100% greenhouse gas emissions at an industrial site. Core to this is the combination of Airborne Wind Energy (AWE) in the form of a wind-kite and Solar Energy, with a Redox-flow Battery storage. To coordinate these assets in one seamless energy provision scheme, ENGIE Laborelec will provide its expertise in the development and installation of the different assets and will also design an intelligent Energy Management System (EMS).

4 key elements – Altogether providing a valuable power solution

For this project, the first choice of PV and AWEC was made based on the combined energy production profile and safety compatibility of these renewable technologies with the Peckensen ATEX (explosive atmosphere) site restrictions. In addition:

1 Airborne Wind Energy Converter (AWEC): At a fraction of the material, installation and maintenance cost of conventional wind turbines, a wind-kite can harness the wind at much higher altitudes than fixed turbines, providing a higher and more constant energy output. This fits well with the baseload energy need of the Peckensen site.

An agreement has been reached with SkySails to supply the kite for the Aquilon project.

2 Solar energy (PV): Another cost-effective, available technology, PV complements the AWEC output profile to supplement the energy need of the site’s baseload phases. PV installation also makes good use of the available space on the site’s building rooftops and unused surrounding areas.

3 Redox-flow battery (RFB): As the AWEC will require periodic extra power during its cycle; for example returning the kite to the ground generator, this demand is met by the RFB eliminating the need to source power from the grid. During such phases, the additional (purposely over-dimensioned) RFB capacity makes it possible to discharge energy to the AWEC while still providing a flat profile to the Peckensen site combined with the PV production; addressing both constancy and energy peak-shaving. Ancillary services or alternative grid stabilising activities can also be exploited whenever relevant for the grid operator or neighbouring communities, thereby creating an additional revenue stream.

4 Energy Management System (EMS): The intelligent management system is a crucial element in the system. It will be designed to automatically align any over- or under- renewable production to ensure delivery of the exact energy needs adapted to the active and passive phases of the gas storage facility. It will also manage control of the connection to the electricity grid for further power distribution and other grid stabilising activities.

An idea worthy of recognition and EU support

With the potential of the “Aquilon” solution to produce 1 GWh of electricity at the Peckensen gas storage facility, which could supply 250 households with electricity for a year, the project is already recognised for its potential to make an important contribution to climate neutrality.

As such, this initiative has been selected for grant consideration by the Innovation Fund small-scale programme of the European Union (an investment of €118 million into 32 chosen small innovative decarbonizing projects across 14 EU Member States, Iceland and Norway). The grants are to support projects aiming to bring low-carbon technologies to the market in energy intensive industries, hydrogen, energy storage and renewable energy.

Successful projects under the call are now starting to prepare individual grant agreements. These should be finalised in the fourth quarter of 2021, allowing the European Commission to adopt the corresponding grant award decision and start disbursing the grants. Projects then have up to four years to reach financial closure.

Everything crossed and double-checked

With such initiatives, everything starts with the idea and preparation:

ENGIE Laborelec was there to help ensure the redaction and good submission of the project file to the Innovation Fund through our Public Funding Support. Our fingers remain double-crossed for our Storengy partners that the project is every success it promises to be on paper.

With this in mind, our expert teams continue to work hard alongside Storengy on the right preparations and execution of this exciting project.