Power utility operators increasingly need to manage and maintain expanding fleets of diverse transformers. Laborelec offers an independent and web-based transformer fleet monitoring service to greatly simplify the task. Backed up by true subject experts, the service features OneBoard, an eminently convenient dashboard designed to visualize transformer fleet health as well as the ageing condition of individual transformers, alerting for any potential issues at an early stage.

Why - Diverse transformer fleets: a challenge for the operator

Transformer fleet management and maintenance is made increasingly difficult by the rising number of transformers used by power utilities today, often as a result of new electrification and decentralized power generation projects. Operators often don’t have a complete view, especially where there are transformers of multiple brands in place, making it a real hassle to monitor individual transformers and identify potential issues in a timely way. Costs can also rise significantly if OEM recommendations for servicing, overhaul, and replacement are routinely followed without fleet managers knowing whether such interventions are absolutely necessary. So, how can you get a better grip on all this?

What - Web-based fleet monitoring backed up by independent experts

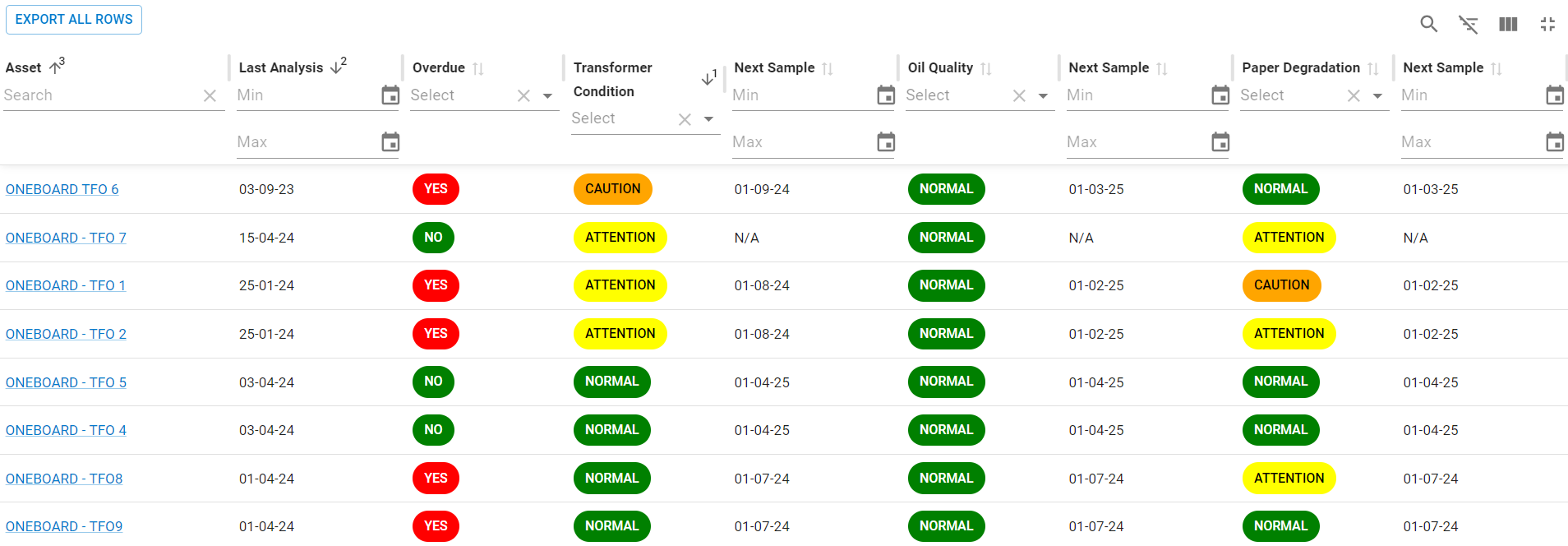

Laborelec’s web-based transformer fleet monitoring service is exactly what fleet managers need. Through the OneBoard dashboard, you get a clear view of overall fleet health as well as on how individual transformers are ageing. OneBoard brings transformer oil analysis results and online monitoring data together into a secure cloud database. Laborelec experts continuously scrutinize the database to identify issues as they arise, raising an alert for the fleet manager if any individual transformer requires action.

Benefits

-

The entire fleet in one dashboard

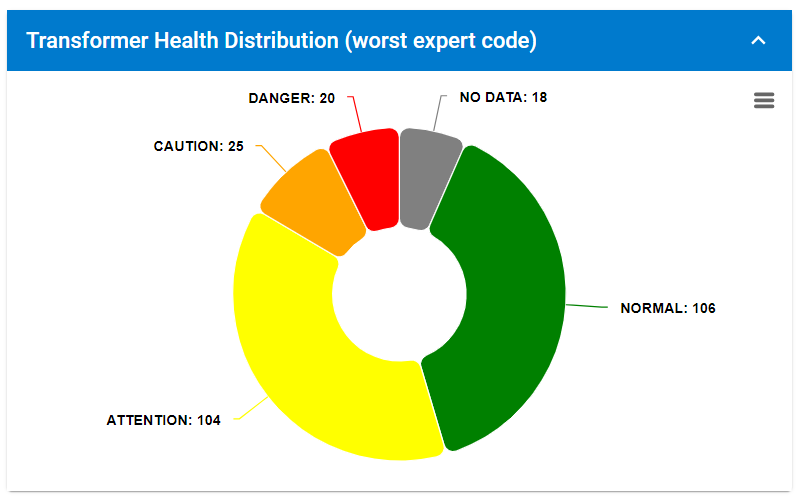

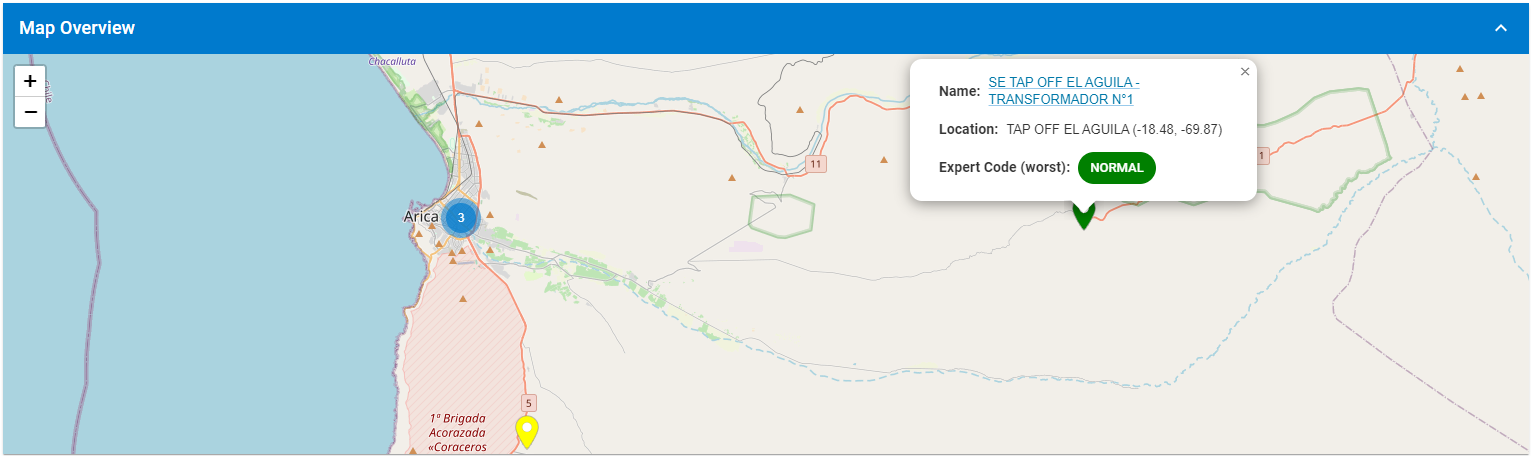

OneBoard collects data from every transformer, displaying both a clear fleet overview and detailed information on each individual transformer.

-

Expert evaluation

OneBoard signals issues based on evaluation by genuine subject experts with years of experience in analyzing transformer health.

-

Combining online and offline analysis

OneBoard combines data gathered from online monitoring systems with laboratory oil analysis results. We can integrate our own lab results with those from other laboratories.

Added value

-

Validated by power utility operators

OneBoard is developed by transformer experts, gathering experiences and user input from an extensive community of power utility operators.

-

Independent advice

Totally independent from OEMs, Laborelec delivers unbiased advice to transformer fleet operators every day.

-

Unrivalled transformer experience

Laborelec has over fifty years of experience of transformer oil analysis and health monitoring. We are currently monitoring many thousands of transformers of various brands around the world.

How this service works

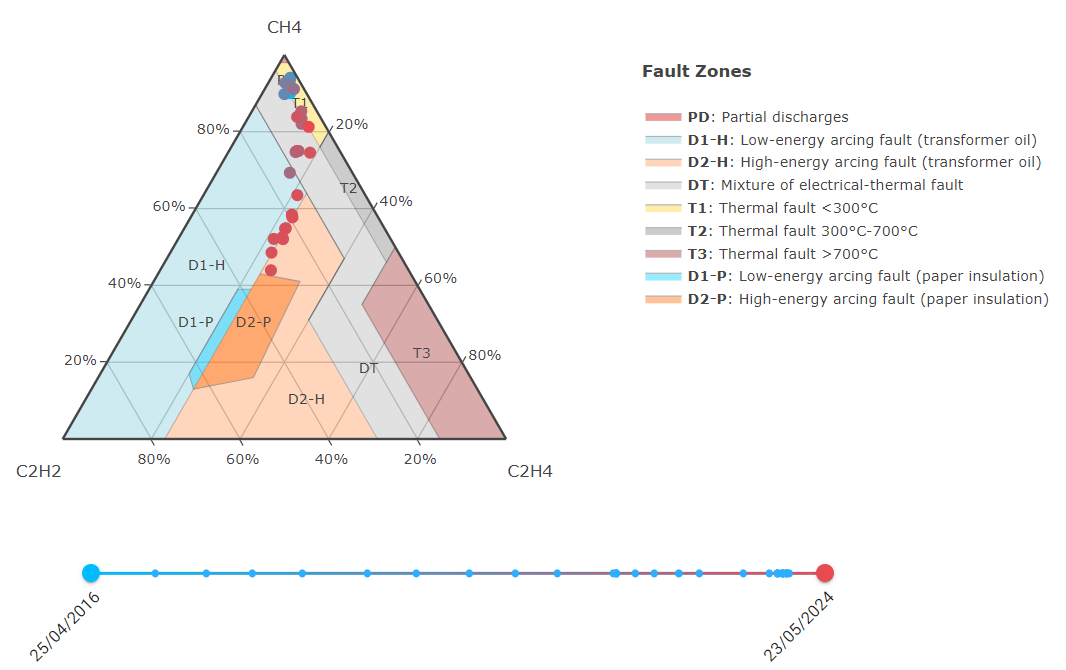

It all starts with transformer oil analysis

Power utility plants have full access to OneBoard if Laborelec monitors their transformer fleets. The service includes a programme of taking oil samples, sent to our laboratory for analysis where our specialists analyse and interpret the results, offer expert recommendations, and update the sampling programme. You, the customer, get prompt access to the results and recommendations through your company’s OneBoard account.

Completing your OneBoard database

You can update and complete your OneBoard database by letting us analyze oil samples from other transformers or have oil analysis results from other labs sent to us for interpretation and recommendation. The outcomes are promptly added to your OneBoard account.

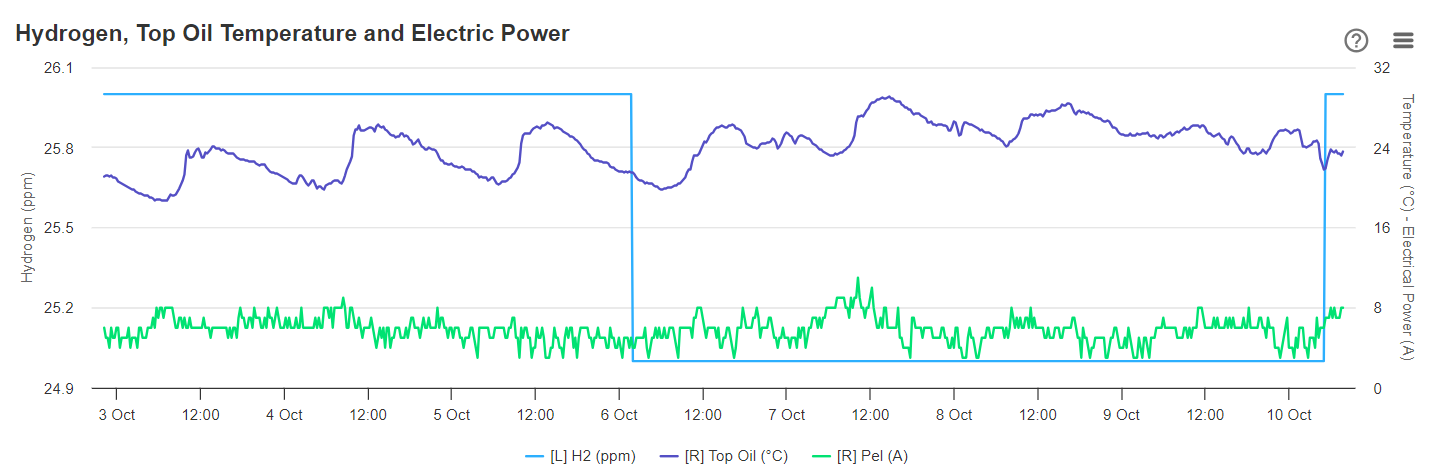

Extending your OneBoard with online monitoring data

By giving Laborelec access to the online monitoring data from dissolved gas analysis (DGA) devices installed on your most critical transformers, we can automatically integrate the data into the OneBoard database, allowing us to further refine our analysis and recommendations.

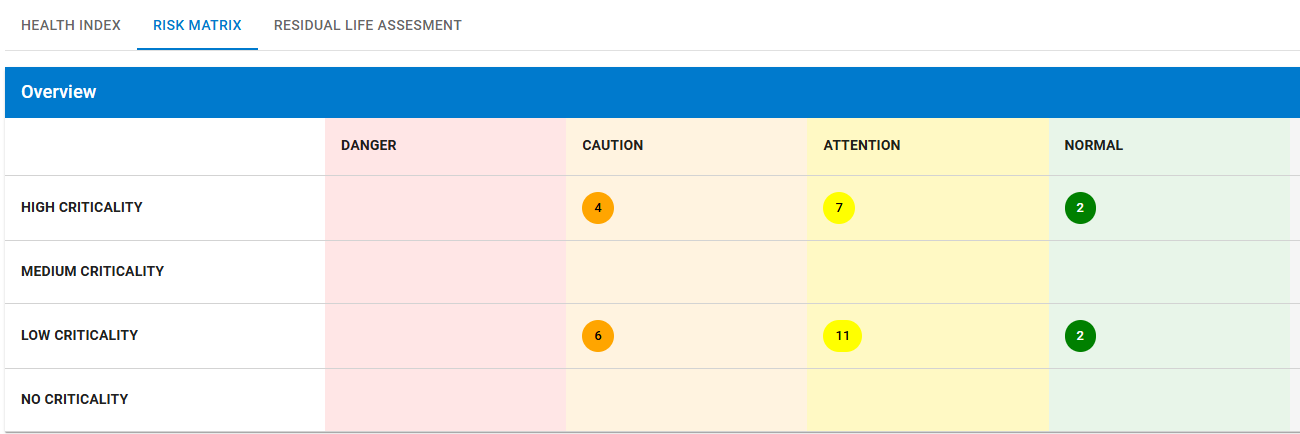

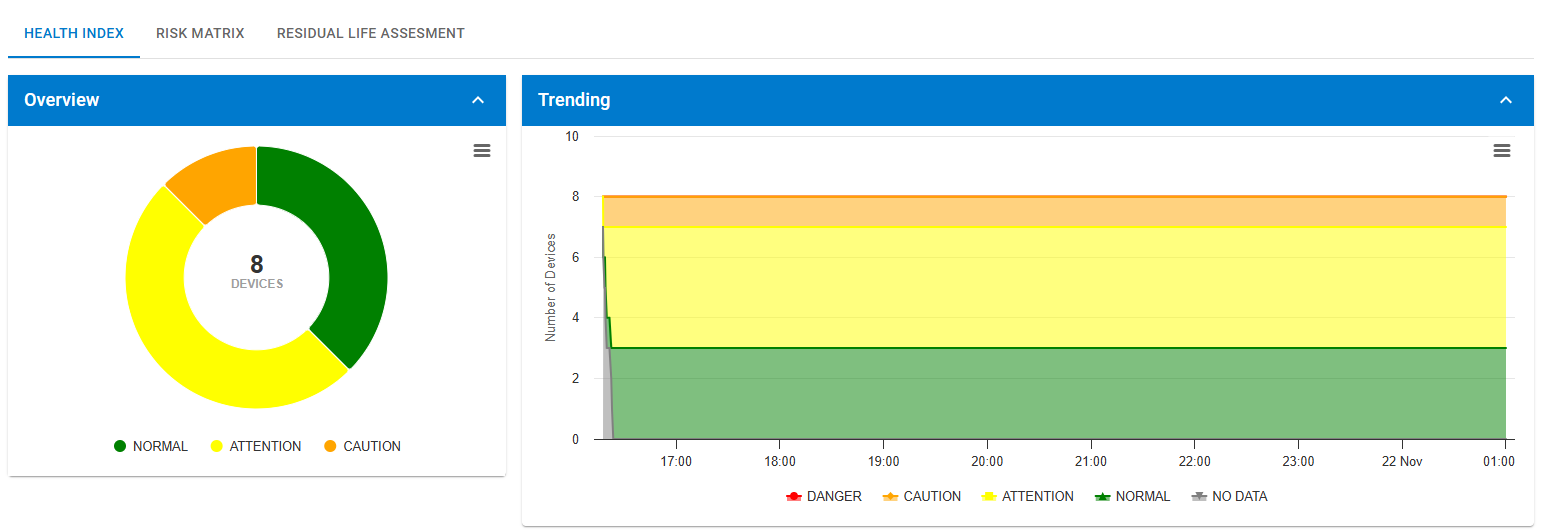

Checking your fleet status and getting notifications through expert alarm management

In OneBoard, you can easily identify which transformers need closer attention. You can also opt to receive notifications about specific transformers.

Advanced features in the premium version

OneBoard’s premium version includes advanced features such as electrical testing results integration, transformer health index calculation, and assessment of remaining lifetime. It also includes advanced search and reporting capabilities as well as the possibility of integrating additional transformer-specific documentation.