A fast, reliable, low-cost solution and service for wind farms

Incorrect north alignment of wind turbine nacelles, leading to inaccurate shadow and noise curtailment as well as unreliable side-by-side turbine performance assessments, is an all too common issue in wind farms. As is the cost and effort of performing a manual correction. ENGIE Laborelec now offers a fast and low-cost alignment solution that outperforms traditional methods both in accuracy and efficiency.

The importance of nacelle north aligment

Historically, wind farm OEMs have often been remiss when it comes to correctly aligning their turbine nacelles to true north. Yet correct alignment is vital as current turbine analysis algorithms use the nacelle’s deviation from true north to determine whether power production should be curtailed for reasons of shadow or noise disturbance. Likewise, side-by-side performance assessment algorithms use the nacelle’s relative orientation to determine the presence of obstacles or wake effects.

Until now, the only solution for operators was to perform a time-consuming manual intervention on each turbine of the wind farm. A step requiring favorable weather conditions for results to be reliable.

An accurate low-cost solution

ENGIE Laborelec has developed a more practical and cost-effective solution to correct a turbine nacelle’s north orientation. We match an appropriate high-definition satellite image of the wind farm with the related SCADA data of each turbine. This allows us to dramatically reduce the time and cost of north alignment projects.

Benefits

Accurate north alignment ensures curtailment algorithms perform in perfect accordance with the operating license, avoiding disturbance claims.

Accurate application of advanced curtailment also ensures that a turbine is used to its full potential as defined by the operating license. This is increasingly important in times of reduced subsidies for operating wind farms.

With correct north alignment, performance analysis algorithms accurately assess the presence and impact of obstacles or wake effects. This supports you in possible discussions with your OEM.

The wind turbine sometimes needs to be oriented to a precisely defined region for maintenance reasons or for safety reasons (f.e. Icing). With a correct north alignment, the wind turbine will be oriented correctly to the demanded position. So no time is lost and no risks are taken due to poor positioning.

Added Value

ENGIE Laborelec’s north alignment service requires no onsite activity and can be carried out in short notice at a surprisingly low cost.

Our experts have extensive wind farm expertise and are familiar with wind turbines and systems of all makes.

How it works

Sourcing an appropriate satellite image

We consult the databases of various satellite image service companies to source relevant images of the given wind farm, along with the date and time at which they were captured. We purchase and download the most appropriate image in high definition.

Gis analysis to calculate offset

We analyze the image in a GIS system, determining each turbine’s real orientation at the given date/time. By combining this with the SCADA data of the turbine, we are able to calculate the turbine nacelle’s north alignment deviation.

Update system parameters

The corrected north offset parameters are subsequently entered into the wind turbine control system.

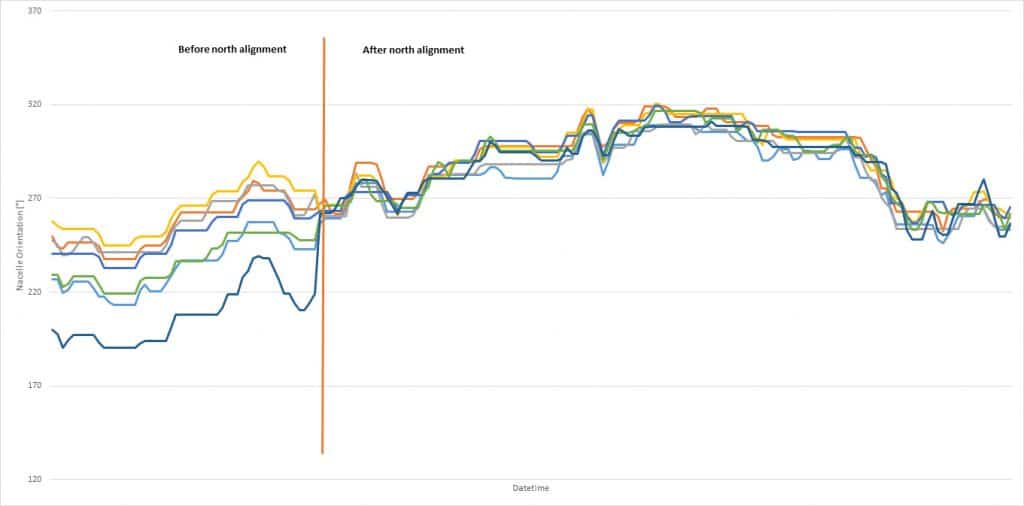

A typical north alignment issue & resolution made tangible