When an asset fails, it’s essential to understand the root cause to prevent reoccurrence and determine liabilities. ENGIE Laborelec provides a comprehensive service so that power plants and industries can find out the root causes of failures and take appropriate action to mitigate risk and ensure business continuity. It also includes support in any litigation.

Understanding failure and preventing reoccurrence

Equipment failure can result in unplanned outages, as well as significant repair costs and business disruption, hugely impacting profitability and insurance risk profiles. So, whenever a failure occurs in mechanical or electrical equipment, there must be a rapid response to immediately address the failure and prevent reoccurrence. But exactly what action is required? Deep insight into the circumstances and mechanisms which led to the sequence of events is essential if appropriate actions are to be defined. That’s why ENGIE Laborelec provides its comprehensive root cause analysis and failure remediation service.

Comprehensive analysis to take the appropriate action

Our multidisciplinary team of experts uses a proven root cause analysis methodology. A systematic, structured approach is applied to preserve, collect and analyze relevant evidence of any kind, including as-found asset condition, operational circumstances, process parameters and human interventions prior to and during the event. The investigation could involve carrying out laboratory procedures such as non-destructive testing, destructive material investigation, and chemical analysis. Then, we iteratively analyze dependencies and contingencies to determine all the factors contributing to the event and identify the root causes. Based on the findings, we provide a solid root cause analysis statement and advise on corrective and preventive measures.

BENEFITS

Avoiding damage and its consequences

Insight into the root causes of a failure allows appropriate actions to be taken, avoiding further damage and preventing further unplanned outages.

Better reliability, availability and safety

Addressing the root causes of events and proposing remedial action improves equipment reliability and availability as well as safety.

ADDED VALUE

Independent

We are independent from equipment manufacturers, providing a service in the interests of asset owners, operators and stakeholders.

Comprehensive multidisciplinary approach

Valuable experience

How it works

We use a proven, structured methodology to conduct holistic root cause analysis. The procedures may be organized step by step to be carried out in parallel or serially, depending on the circumstances.

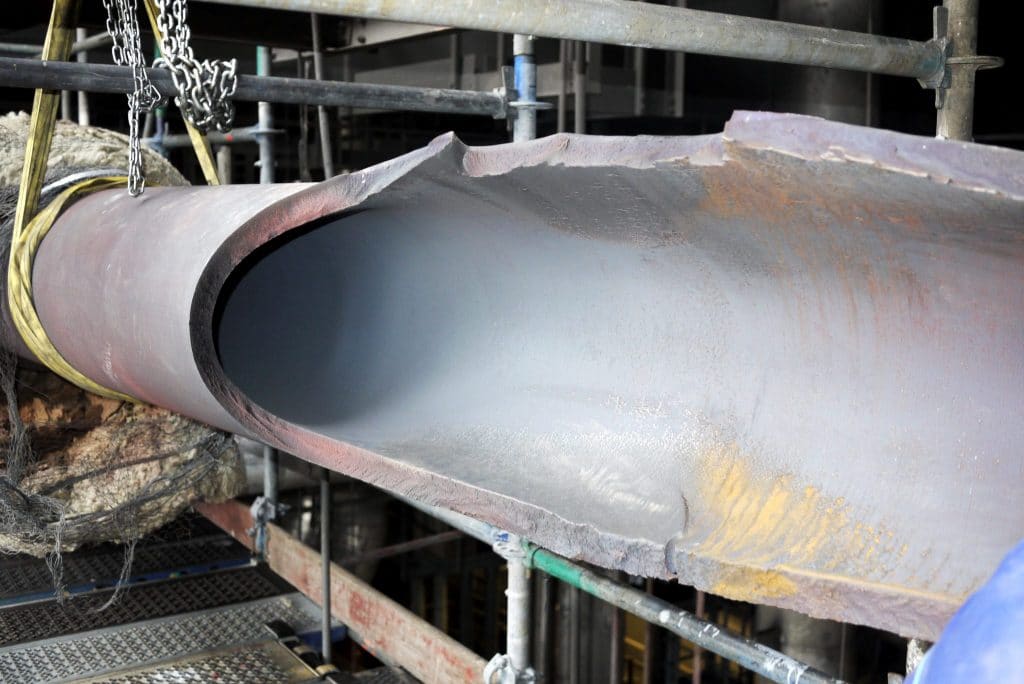

Fact-Finding

When a failure occurs, the essential first step is to preserve and meticulously collect all information and data relevant to the RCA investigation. This involves rapid-response forensic on-site inspection (where needed), as well as the collection of historical and operational data from the time prior to and during the event, including relevant equipment parameters and the sequence of human intervention and operator actions. All such data are documented in a structured way. Damaged hardware may then be selected for further investigation.

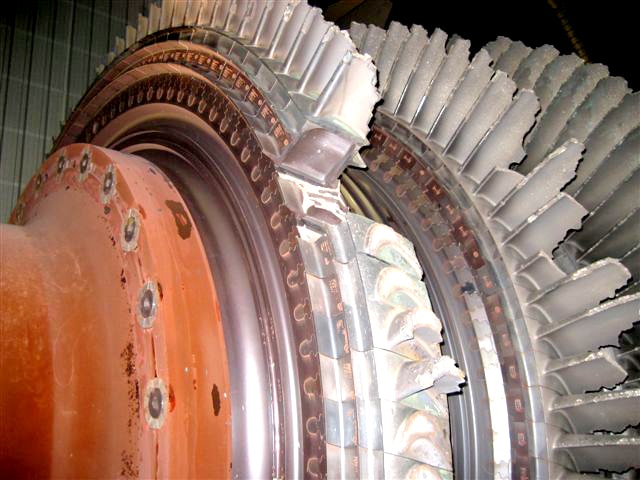

On-site and laboratory testing

We duly define and carry out a program of on-site and off-site laboratory tests to evaluate the condition and behavior of relevant components. Tests may include:

Identifying all potential causes and contributors

With the comprehensive data and test results to hand, we analyze the dependencies and contingencies to determine all the contributing factors. Experts from the various domains work closely together to develop a fault tree or causal graph against which different hypotheses are iteratively evaluated to converge on the actual root cause. Additional factors supporting a hypothesis may be gathered from operating experience at other power plants or industrial facilities. In the report, we list all causes potentially contributing to the failure event and their significance.

Advising appropriate action

Based on our findings, we provide solid advice including a list of appropriate corrective and preventive measures to mitigate risk. On request, we also carry out post-factum evaluation of the effectiveness of the measures taken. ENGIE Laborelec offers complementary technical consultancy services. In this respect, we can also prevent damage and failure by proactively performing risk assessment and condition monitoring on assets.