Cables, cable joints, cable terminals

Increasing availability

A cable breakdown usually means an unexpected production stoppage. This, in turn, often entails considerable financial consequences. An appropriate condition monitoring of cables, cable joints, and cable terminals — in short

cable systems — minimizes the risk of such incidents.

Multi-disciplinary know-how

Cable systems are subject to numerous interactions between electrical, chemical, and mechanical factors. Therefore, analyzing just one of these aspects is not enough. A comprehensive understanding of a cable system requires a multi-disciplinary analysis.

Laboratory for electricity and materials study

Laborelec has a team of expert engineers and technicians who measure and assess the electrical characteristics of cable systems. They collaborate

closely with our materials experts who analyse the mechanical and chemical status of the insulation. Together, they discuss the results. Often, the materials analysis sheds new light on the electrical measurements, and vice versa.

Integrated results, reliable advice

Integrating the results from both laboratories produces an accurate and complete image. This enables our experts to provide clear and reliable advice for:

• Cable purchasing and replacement

• Status assessment of existing cable systems

• Analysing the cause of incidents

Services

Purchasing advice

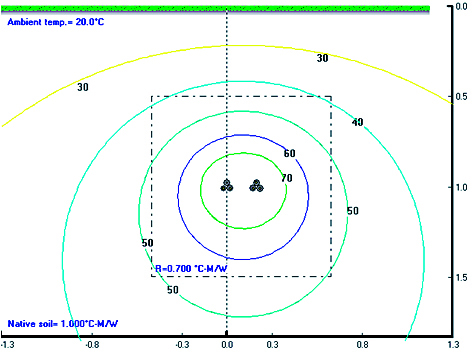

A reliable power supply begins with the right cable at the right place. This choice, however, depends on a complex set of factors including the expected cable load, the cable location, the depth to which it is buried, the type of soil,

as well as the proximity to other cables.

Our experts use simulation software to calculate the right type of cable for each individual situation. When appropriate, they also provide advice on cable installation.

Preventive audit

Many old paper/lead cables are nearing the end of their service life, while XLPE cables often start exhibiting faults after a limited number of years

in operation. The risk of a cable breakdown is therefore real and the financial consequences are often considerable.

Preventive analysis of cable systems minimizes the risk of an unexpected breakdown. It also enables to timely budget necessary cable replacements in annual investment plans.

Our experts analyze the cables, cable joints, and cable terminals, and draw up a precise description of the present situation. They provide advice for each connection tested by using a green, yellow, orange, or red label.

Analyzing breakdowns

When an incident with a cable system occurs, Laborelec first determines whether other cable systems in the company are at risk for similar problems. Our experts also execute a root cause analysis of the damaged cable systems. There are several potential causes, including:

- Damage that occurred during installation

- Poor quality insulation and/or protective

shield material - Accelerated ageing due to overload or

inadequate sizing - Degradation of the insulation by ambient factors

We also evaluate what the best solution is: to repair or to replace. In both cases, we can advise you on which equipment and materials to use.

Electrical measurements

Measuring one single electrical characteristic is rarely sufficient for a complete diagnosis of a cable system. Our experts usually opt for a combination of various measurements. They come on site with our measurements vehicle, a mobile laboratory equipped for all primary non-destructive tests, including loss factor, partial discharges, polarization index, and external sheath test. If necessary, additional electrical or material tests will be carried out in our laboratory.

Loss factor and general status of the insulation

The loss factor, also called tg or TD, is an indication of the overall degradation of a cable’s insulation. It can also indicate the humidity and partial discharges in a cable. Laborelec can measure the loss factor at 0.1 Hz for voltages of up to 42 kV RMS.

Partial discharges and risk of breakdown

Partial discharges damage the insulation and therefore increase the risk of breakdown. Our experts measure partial discharges using an amplifying wave. With this method, the measuring time is limited and the risk of further cable degradation minimized. The location, nature, and size of the discharges are recorded (for voltages up to 42 kV RMS).

Total Petrochemicals France Usine de Gonfreville integrates cable management in predictive maintenance plan

‘The Total Petrochemicals France plant in Gonfreville is supplied by 20 kV PILC cables that were installed in 1970. Any fault that might occur in these cables could generate an unexpected stoppage, resulting in considerable losses,’ explains Hervé Leprévost, Maintenance Technician at Total Petrochemicals. ‘In order to identify any potential issue, we have asked Laborelec to carry out a measurement campaign on all three-phase cables. We have incorporated the results of this analysis in our predictive

maintenance plan.’

Polarization index as an additional source of information

The polarization index (PI) is a good additional source of information on the degradation status of a cable. The evolution of the resistance over time can be measured by applying a DC voltage to the cable. Our experts can carry out this measurement onsite or in our laboratory.

Dielectric quality of the insulation

Our experts increase the voltage on a cable section until it discharges. The discharge voltage gives a clear indication of the dielectric quality of the cable insulation. Unlike most of our other electric cable tests, this is a

destructive test that is carried out in our laboratory.

Netmanagement Wallonia: Rapid results with simulation software

Simulation software allows us to rapidly and accurately define the relation between the load profile of a cable and its temperature profile. For distribution grid operator Netmanagement Wallonia, this is one of Laborelec’s decisive advantages. The company manages about 14,000 kilometres of distribution cables. Bernard Sturbaut, of Netmanagement Wallonia’s engineering and design department: ‘We have quite a good knowledge of cables, but as soon as things get complex, we call upon Laborelec. They have specialized expertise in-house, as well as the right software and considerable experience. Recently, one of our cables broke down because of overheating — something we had never encountered before. Laborelec was called in and detected the cause by means of a materials analysis and software simulations. Subsequently, they also defined the necessary characteristics for the new replacement cable.’

Materials analysis

The cause of a cable breakdown can be detected through a thorough materials analysis. This analysis enables us to establish, for instance, whether the cable system is:

- Correctly installed

- Exposed to water

- Overheated at certain points

- Affected chemically due to a particular soil composition

As soon as the cause of the fault is established, Laborelec determines whether other cables could be subjected to similar degradation mechanisms.

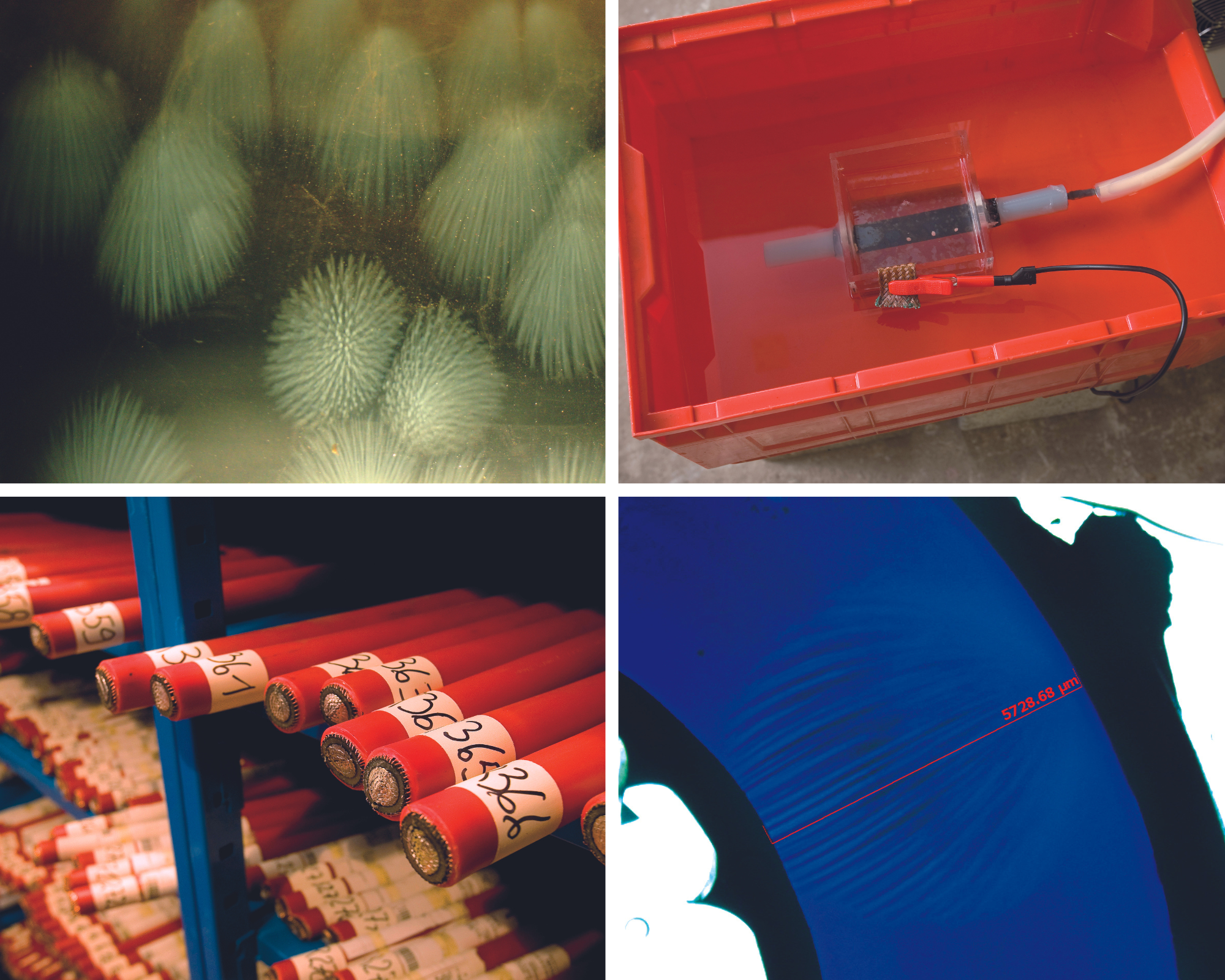

Well equipped laboratory

Our materials experts begin each analysis with a visual inspection. For further research, they can rely on a broad range of instruments including an IR spectrometer, an X-ray fluorescence metre, a differential scanning calorimeter, a Karl Fischer titrator, and a stereomicroscope.

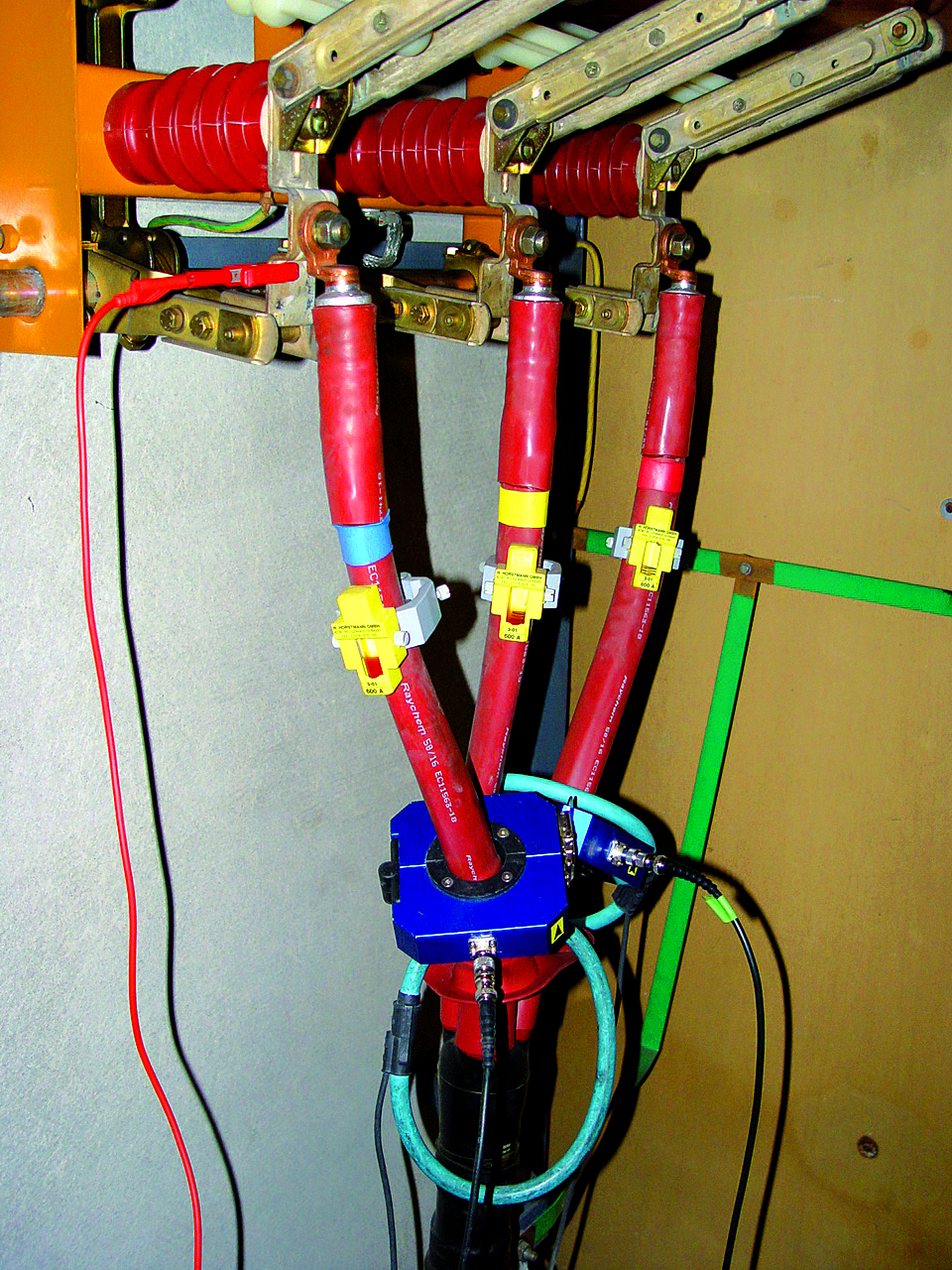

Quality of cables joints and cable terminals

In the case of cable joints and cable terminals, a lack of professionalism during installation is often the cause of subsequent faults. Our experts open the joint and remove the various insulation layers one by one. That way, it is immediately apparent if the stitches between the layers are sufficiently strong. Thereafter, they submit the insulation material to further analysis.

Lanxess NV: ‘Laborelec’s advice supports our investment decisions’

The chemical company LANXESS NV runs two plants in the Antwerp harbour. It utilizes numerous 36 kV cables to supply its continuous production. ‘Laborelec’s experts identified the cause of a cable breakdown for us,’ says Johan Doms, Plant Engineer Energy. ‘We then asked for a preventive analysis for the rest of our cable network. They drew up a report for a wellchosen sampling of cables, using colour codes to indicate their status. This forms a strong basis for our investment planning. Because Laborelec is independent from cable producers, we receive unbiased and economically optimal advice.’

Degradation mechanisms of pilc cables

Paper Insulated Lead Covered (PILC) cables are no longer manufactured, but many of them are still in service. The degradation of the insulation paper is a measure of their remaining service lifetime. Our experts measure the degree of polymerization and the water content of the insulation paper — two important parameters. In addition, the degree of acidity is also measured and the insulation is inspected visually to identify any gas bubbles. A last important test is the analysis of the oil in which the insulation paper is immersed.

XLPE cables and water peneration

Water penetration is a frequent cause of faults in the case of cross-linked polyethylene (XLPE) cables. Our experts measure the water content of the insulation. They then make very thin insulation slices and inspect it for the presence of water trees. Other analyses carried out on XLPE cables include

the detection of impurities in the insulation, the analysis of the morphology of the insulation, a molecular analysis of the insulation and of the semiconductor, and an inspection of the thermal history of the insulation.

Research projects

Laborelec not only has field experience with cable systems, it is also active in numerous research projects. This results in an additional insight into the fundamental aspects of cable degradation, which is extremely useful when assessing faults.

- Research on water trees: Laborelec has developed a unique method that enables us to accelerate the growth of water trees. Using this method, we can identify which XLPE cables are the most sensitive to this phenomenon.

- Development of a cable library: Laborelec has currently have a collection of more than 300 reference cables. This allows us to immediately compare any used cable with a new cable of the same type.