ENDEL and TRACTEBEL, two subsidiaries of ENGIE, won a strategic batch for the replacement of primary components for EDF

A first integrated offer by ENGIE in the area of services to the nuclear sector

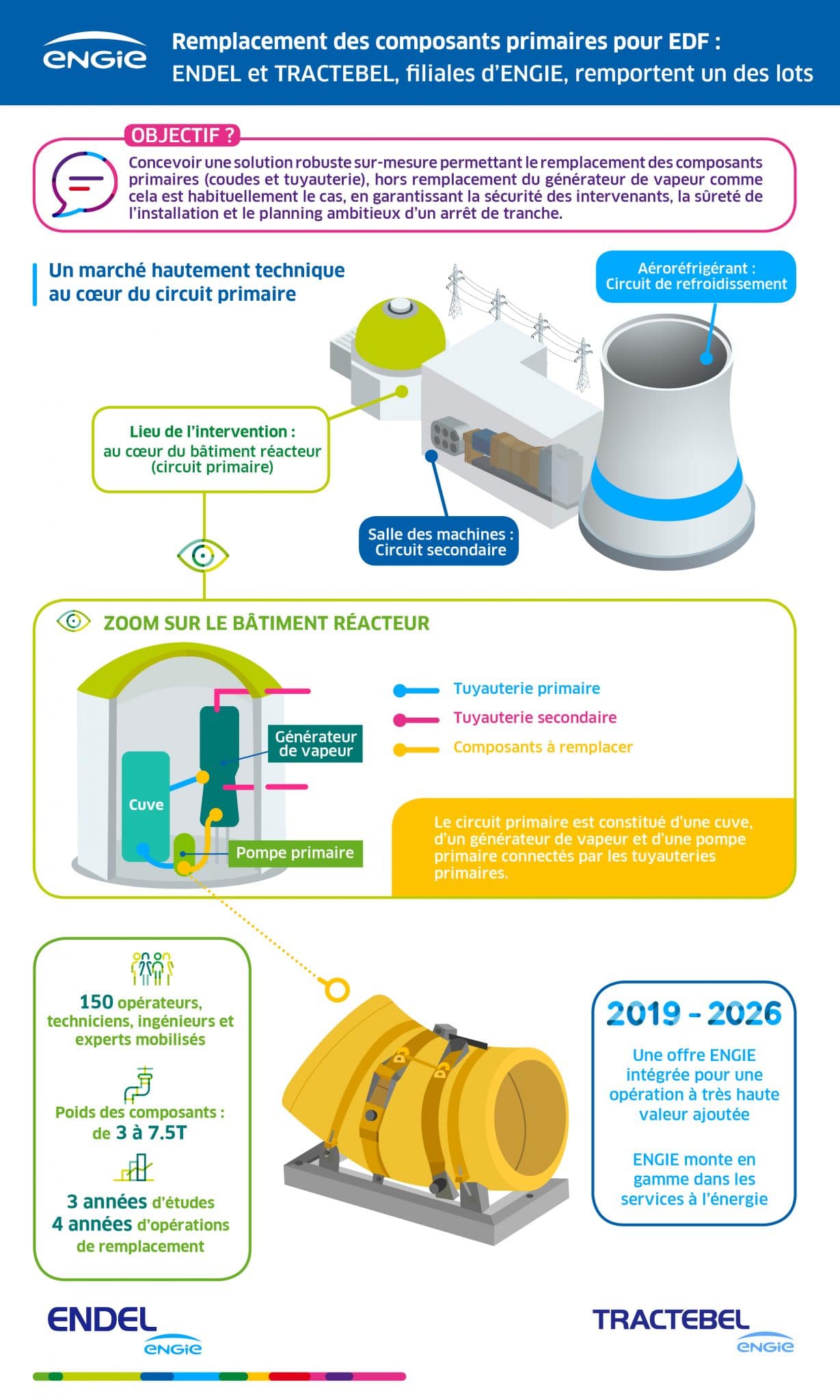

Following a competitive dialogue initiated by EDF in 2017, ENDEL and TRACTEBEL, two subsidiaries of ENGIE, have just won a strategic batch of the contract for the replacement of primary components including pipes and pipe bends, for 900 Mw power stations. Relying on a temporary joint-venture combining the most expert operating, engineering and intervention skills available within ENGIE Group, ENDEL and TRACTEBEL will conduct this demanding intervention by relying on their Group partners. A very high added-value operation that will mobilise expert teams over several phases until 2026.

A groundbreaking operation requiring meticulous preparation

As part of its strategy to prolong the lifetime of its 900Mw power stations, EDF entrusted to a temporary joint-venture led by ENDEL and TRACTEBEL the replacement of several primary circuit components weighing between 3 and 7.5 tons, including pipes and pipe bends. This highly technical project will mobilise the teams of several ENGIE subsidiaries at the core of the power station. The replacement of the components will be staggered over several phases until 2026.

During the next three years, the first phase will be dedicated to all the generic studies and the Qualification of the Maintenance Operation. As of 2022, the second stage of the operation will begin and will consist in the specific studies and the preparation for the interventions. Finally, starting in 2023, onsite interventions will begin. Each intervention will require 6 months’ work. The completion of this high-stakes project involves taking into account major physical and technical constraints, while securing unit shutdown periods. The cutting-edge technologies deployed must meet geometric tolerances of 0.1 millimetres to position and weld these large parts.

A first integrated offer by ENGIE at the service of a complex intervention

ENGIE Group can rely on its many entities strategically positioned due to their nuclear business lines. Each of these entities demonstrates a wide range of skills, recognised both in France and abroad, in conducting complex operations, and has been supporting EDF with its safety challenges for many years. To meet all the requirements induced, ENDEL and TRACTEBEL formed an integrated team with their partners.

Relying on their experience in the Qualification of Maintenance Operations and complex handling operations, ENDEL’s teams will oversee the project and will, in particular, conduct the welding operations for the primary component circuit, a rare skill in the sector.

Relying on the feedback from a similar operation conducted abroad, TRACTEBEL – which has been otherwise involved in the French nuclear sector for many years – will provide its know-how and expertise in the area of primary circuit engineering to the joint-venture. ENGIE Laborelec is an expert in electrical technologies that specialises in non-destructive testing operations in particular and will intervene during the study phase in order to design, develop and qualify a bespoke robotised solution. The aim is to have a cutting-edge technology able to shave welds and check areas inaccessible to any human intervention. TECNUBEL will develop the sealing solutions specific to the primary circuit and will proceed with the decontamination of this zone located at the core of the power station, another rare skill among energy services actors.

“We are proud of the trust shown by EDF to conduct this operation” Emeric Burin des Roziers, the CEO of ENDEL, affirmed. “The great strength of our integrated joint-venture lies in how our internal expertises and experiences complement each other. Our renowned respective experiences in the area of energy services now enable us to prepare the first replacement operation for primary components of this magnitude, excluding steam generator replacement. This acknowledgement is opening up great prospects for us.”

“This cross-functional success of our ENGIE entities shows our ability, as a collective, to help our clients meet their major industrial challenges” declared Olivier Biancarelli, Deputy General Manager for ENGIE Group, in charge of the Global Business Line Customer Solutions, TRACTEBEL and ENGIE Impact. “Our TRACTEBEL nuclear engineering teams and our ENDEL energy services teams, along with other Group entities, were able to convince EDF of their expertises to conduct these future high value-added interventions on the primary circuits of French nuclear power stations. The trust placed in us through this contract confirms our ability to meet the stringent requirements pertaining to our clients’ nuclear safety.”

About ENGIE ENDEL

ENDEL, a subsidiary of the ENGIE Group, with a solid position as a leader in nuclear services and industrial maintenance, is committed to energy and digital transition. ENDEL aims to participate in sustainable and profitable growth. It is ENDEL’s ambition to be the reference for industrial service provision businesses in the most demanding environments as far as security and quality are concerned.

For its customers, ENDEL wants to be a natural and decisive partner that builds with them the best solutions to meet their industrial challenges. ENDEL therefore wants to contribute to the influence of French industry.

About ENGIE TRACTEBEL

A major player of the energy transition, TRACTEBEL, an ENGIE subsidiary, helps its clients by offering a full range of engineering and consultancy services covering the whole life cycle of their projects, from the strategy and design, up to the operational phases. With 5,000 experts and a presence in over 70 countries, we are able to offer our clients multi-sector solutions including nuclear, water and urban infrastructures. Acknowledged as one of the main global companies in engineering consultancy and boasting over 150 years’ experience, our mission is to play an active and concrete part in building the world of tomorrow.