Any outage of a power plant comes with both risks and opportunities with respect to overall plant performance. How to make the best of it? ENGIE Laborelec’s innovative Performance Guard service allows you to evaluate a given outage’s impact on plant performance and to define and implement corrective actions where required.

Outages: risks and opportunities

Outages are among the most critical moments in the lifecycle of a power plant. Changes to the installation made during an outage can unintentionally result in additional fuel costs or reduced output. On the other hand, any outage provides an excellent opportunity to retune the installation and regain previous performance losses. While a standard post-outage performance test can provide a general evaluation, it will not uncover the underlying mechanisms or highlight improvement opportunities.

Securing and improving the performance level

To take full advantage of these opportunities, ENGIE Laborelec has developed the Performance Guard service, combining an in-depth review of pre- and post-outage plant operating parameters with independent calculations and tests on key equipment. This allows the causes of a possible performance loss to be precisely determined and aspects needing further optimization to be identified. We can then secure the plant performance level and advise on ongoing improvement.

Benefits

By analyzing process parameters and not just output results, we pinpoint exactly what happened as a result of the outage.

The service is like an insurance policy, allowing you to take quick action to undo any outage-induced performance loss.

Our analysis includes benchmarking your plant performance against similar plants all over the world, allowing you to boost your insight into operation and performance.

Added Value

ENGIE Laborelec’s vendor-independent approach, with independent calculations and testing, provides fresh insight into how to better secure your own interests rather than those of the OEM.

We have more than 50 years of field experience in power plants all over the world in a diverse range of climate conditions and local circumstances. Specialized lab equipment and expertise is on hand in all the relevant domains, including materials technology, chemistry, mechanics, and electromechanics

How it works

Reviewing critical performance

Crucial process changes can often be subtle and hard to detect. Our experienced performance engineers conduct an in-depth review of the critical performance aspects before and after the outage, using dedicated top-notch software and interrogating the trends and results based on our worldwide field experience. This provides exceptional insight into the most important process changes resulting from the outage and their impact on plant performance.

Creating pre- and post-outage snapshots

Prior to launching the outage, we create a ‘fingerprint’ or ‘snapshot’ of the plant’s operational status by recording all the operational parameters. The results are summarized in a comprehensive set of 15 dashboards. Immediately after the outage, we repeat this procedure, combined with a series of tests such as a condenser tightness test and an air filter qualification test.

Any outage of a power plant comes with both risks and opportunities with respect to overall plant performance.

Increased staff awareness through rapid feedback

Initial results and the corresponding recommendations are available within two weeks of the outage, giving rapid feedback to stakeholders and the teams involved, allowing swift action.

Subsequent support

If required, ENGIE Laborelec can also provide support for subsequent corrective actions. This could include reviewing and tuning control loops, assessing the vibrational shaft behavior, carrying out additional ISO and ASME performance tests, or peer-reviewing the gas turbine, boiler, generator and transformer outage reports. In addition, we offer a quarterly performance monitoring service.

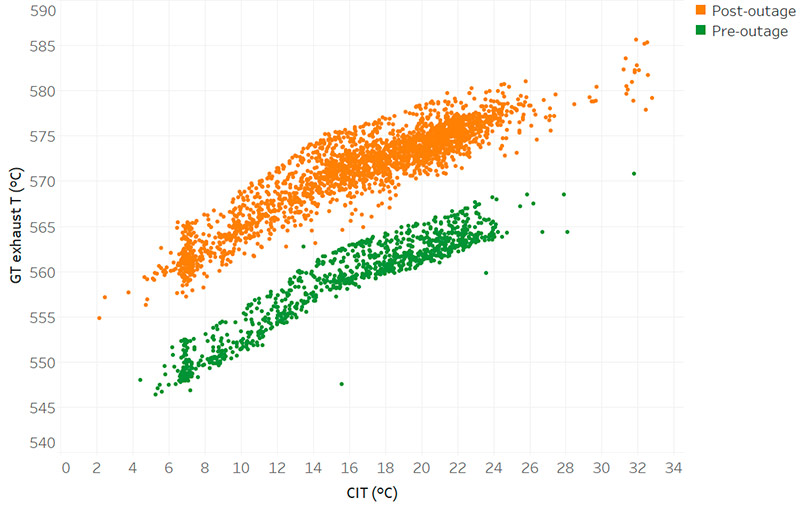

Performance Guard reveals a significant difference between pre- and post-outage GT exhaust temperatures, indicating possible combustion tuning issues.